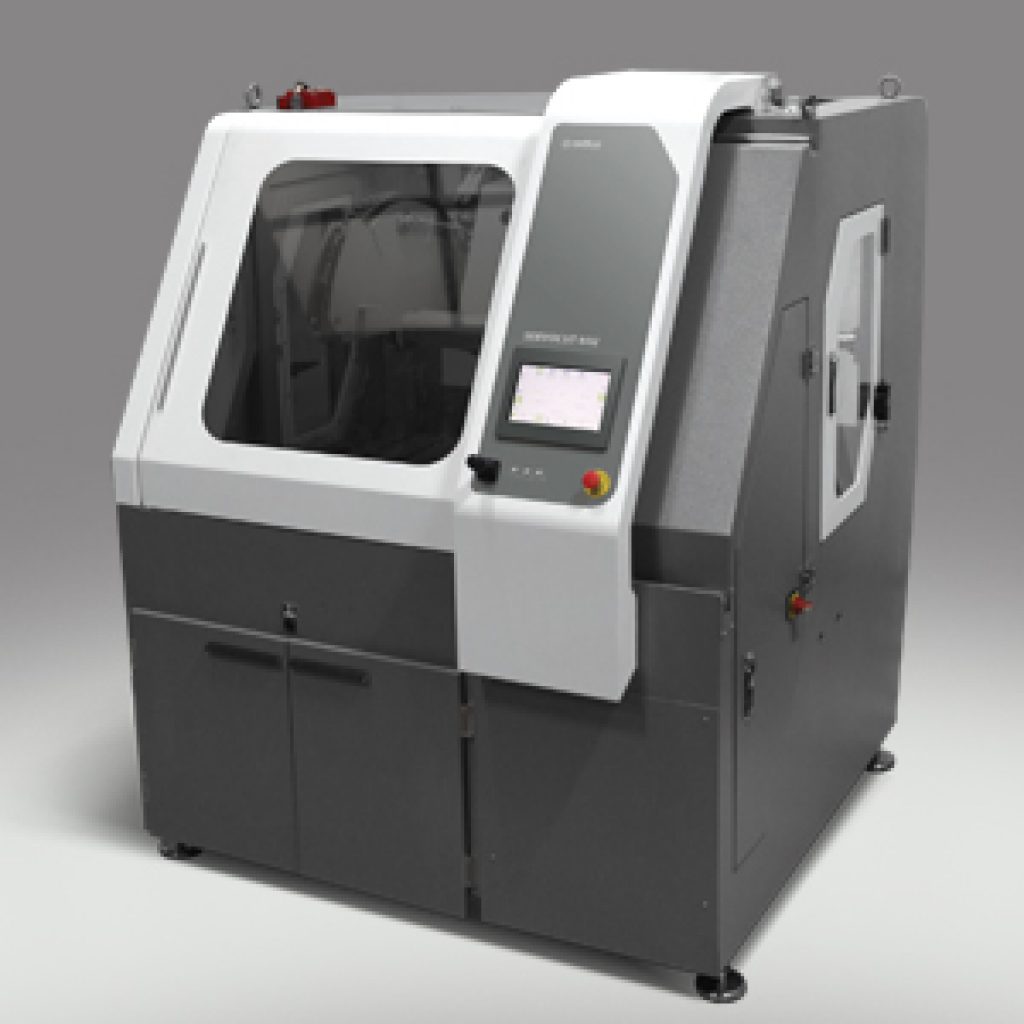

Metkon Servocut 602 Multi-Target Automatic Cutting Machine

Features

Small Footprint, Large Cutting Capacity

Powerful Cutting Motor!

Description

Multi-Target Automatic Cutting Machine

Designed for cutting large and multiple specimens, the Servocut 602 has the ability to work with cut-off wheels up to 600 mm, a cutting capacity up to 225 mm solid stock, or 100Hx500D mm for rectangular specimens (cutting capacity can be increased up to 200Hx550D mm with optional Combined Cut feature), and uses a powerful 15 kW cutting motor.

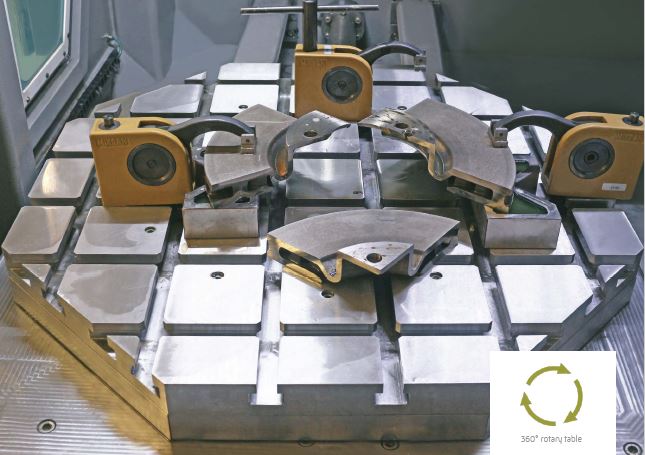

With a unique belt protection system, with electronic brake system, a variable cut-off wheel speed 600-2400 RPM, and the ability to set fixed peripheral speed of cut-off wheel from 20 to 60 m/s, Includes an overload display and protection system, accurate Servo motor driven table and wheel movement for precise and fast positioning. Joystick adjustable speed control, stainless steel table (772x710mm) with 560 mm Y-axis movement range, Servo motor driven cut-off wheel positioning system on X-axis, 540 mm positioning range on X-axis, and includes an advanced cutting methods: “Serial Parallel Cutting” for slicing multiple pieces from a specimen automatically in one cycle. “Multi Target Cutting” for cutting up to 20 different clamped specimens on the table to be cut automatically in one cycle.

Programmable with9.7″ HMI touch screen control, Siemens PLC control unit, automatic cut-off wheel diameter measurement and automatic starting position adjustment according to cut-off wheel wear.

Positioning System allows clamping several components simultaneously, with automatic chop cutting and automatic table feed cutting systems, together with automatic cutting feed rate control, with extra advanced cutting methods: “Multi-Target Cutting, Serial Parallel Cutting, Rapid Pulse Cutting, Table Oscillation Cutting, Instafeed Cutting, Automatic Chop Cutting, Automatic Table Feed Cutting, Joystick Cutting.” Powerful LED illumination, robust construction.

Ready for operation. But without clamping devices, or recirculation cooling tank.

Includes a standard set of cutting consumables composed of;

*An assortment of 10 cut-off wheels with 600 mm dia.

*5 lt of METCOOL cooling fluid.

*400 V, 3 phase, 50/60 Hz.

Technical Specifications

| Order No | 14 87-AX | 14 87-AX-R |

| Model | 602-AX | 602-AX-R |

| Max. Cut-off Wheel Diameter | 600 mm | 600 mm |

| Max. Cutting Capacity for Round Samples, HxD | 225 mm | 225 mm |

| Max. Cutting Capacity for Rectangular Samples, HxD | 100×500 mm | 100×500 mm |

| Z-Axis Travel, (mm) | 340 mm | 340 mm |

| Y-Axis Travel, (mm) | 560 mm | 560 mm |

| X-Axis Travel, (mm) | 540 mm | 540 mm |

| T-Table Dimension, (mm) | 772×710 mm | 772×710 mm |

| T-Slot dimension, (mm) | 12 mm | 12 mm |

| Cutting Motor Power (S1) | 15 kW | 15 kW |

| Variable Wheel Speed | 600-2400 RPM | 600-2400 RPM |

| Wheel Diameter Measurement | Standard | Standard |

| Constant Peripheral Wheel Speed | Standard | Standard |

| Cutting Feed rate, (μm/s) | 20-5000 μm/s | 20-5000 μm/s |

| HMI Touch Screen Controller | 9.7 inch | 9.7 inch |

| Chop Cutting in Z- Axis | Auto | Auto |

| Table Feed Cutting in Y-Axis | Auto | Auto |

| Parallel Cutting in X-axis | Standard | Standard |

| Multi Target Cutting | Standard | Standard |

| Table Oscillating Cutting | Standard | Standard |

| Rapid Pulse Cutting | Standard | Standard |

| Smart Feed Control | Standard | Standard |

| StepCut; Segment Cut; Diagonal Cut | Optional | Optional |

| Automatic Cleaning System | Optional | Optional |

| Central Lubricating System | Optional | Optional |

| Size, WxDxH, (cm) | 184x173x236 | 184x173x236 |

| Weight | 1600 kgs | 1600 kgs |

| Recirculation Cooling Unit | 200 lt | 200 lt |